New

Product

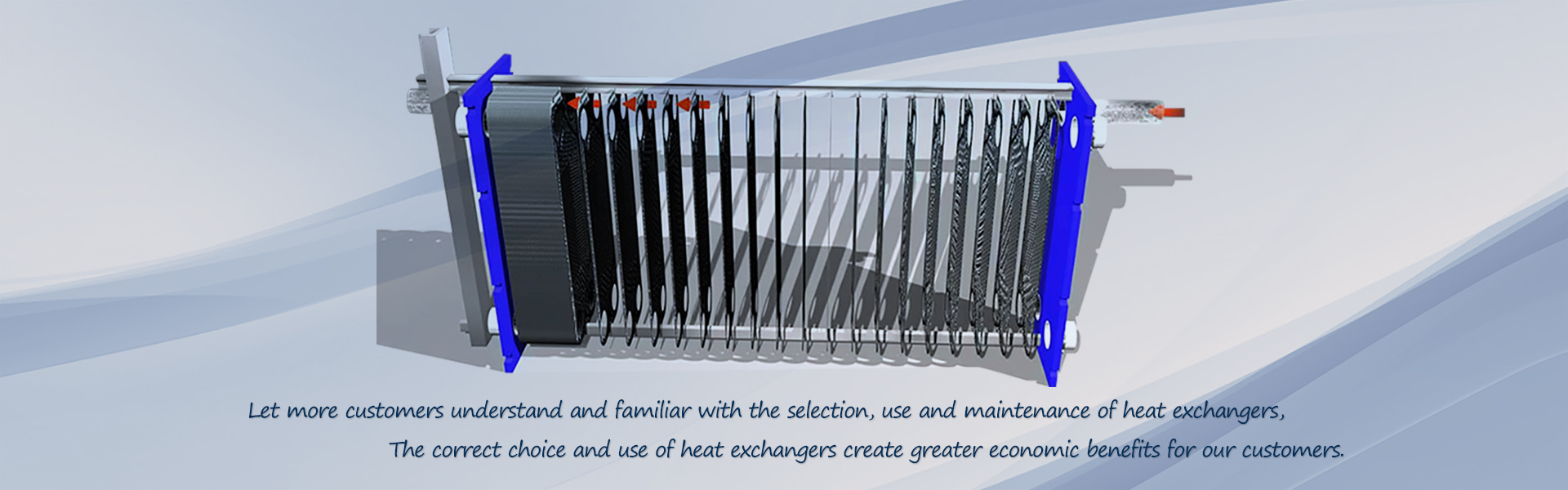

- Detachable plate heat exchanger

- Domestic plate heat exchanger seal gasket

- Semi welded plate heat exchanger

- Brazed plate heat exchanger

- Welded plate heat exchanger

- Detachable frame

- Heat recovery / heat exchange unit

- Wire winding hydraulic press

Hot news

Company news

The Method of Improving Logarithmic Mean Temperature Difference in Plate Heat Exchanger

1, plate heat exchanger flow patterns are countercurrent, downstream and mixed flow pattern.

Under the same operating conditions, the logarithmic mean temperature difference is the largest in the countercurrent flow, and the flow rate is the smallest, and the mixed flow pattern is between the two.

The method of increasing the logarithmic mean temperature difference of the heat exchanger is to use the mixed flow pattern of countercurrent or countercurrent as far as possible, to increase the temperature of the hot side fluid as much as possible and to reduce the temperature of the cold side fluid.

2, for a single process layout of the plate heat exchanger, for easy maintenance, fluid inlet and outlet pipe should be arranged as far as possible in the heat exchanger fixed end plate side.

The greater the temperature difference of the medium, the stronger the natural convection of the fluid, the more obvious the effect of the retention zone.

So the media inlet and outlet position should be carried out by the hot fluid into the cold fluid into the out of the layout, in order to reduce the impact of the retention zone, improve heat transfer efficiency.

Under the same operating conditions, the logarithmic mean temperature difference is the largest in the countercurrent flow, and the flow rate is the smallest, and the mixed flow pattern is between the two.

The method of increasing the logarithmic mean temperature difference of the heat exchanger is to use the mixed flow pattern of countercurrent or countercurrent as far as possible, to increase the temperature of the hot side fluid as much as possible and to reduce the temperature of the cold side fluid.

2, for a single process layout of the plate heat exchanger, for easy maintenance, fluid inlet and outlet pipe should be arranged as far as possible in the heat exchanger fixed end plate side.

The greater the temperature difference of the medium, the stronger the natural convection of the fluid, the more obvious the effect of the retention zone.

So the media inlet and outlet position should be carried out by the hot fluid into the cold fluid into the out of the layout, in order to reduce the impact of the retention zone, improve heat transfer efficiency.

Related articles

- Congratulations on our company's quality management system, occupational health management system and environmental management system certification.

- Manufacturing Technology of Rubber Seal Gasket for Plate Heat Exchanger

- Precautions for replacement of plate heat exchanger gaskets

- Fixed method of Heat exchanger gasket

- Temporary Treatment of Aging of Plate Heat Exchanger Gasket

- Detachable plate heat exchanger which parts are formed

- work circumstances of the plate heat exchanger

- The best way to buy plate heat exchanger products

- Temperature and Pressure Requirements for Plate Heat Exchangers

苏公网安备32028102001776

苏公网安备32028102001776